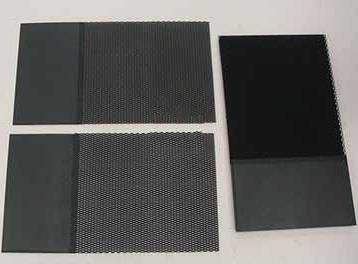

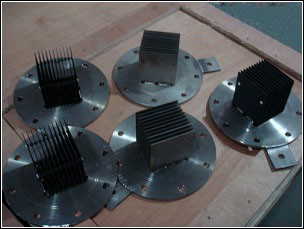

| During process of water treatment including sea water desalination/electrodialysis(ED), industrial wastewater treatment, caustic soda, hydrogen and oxygen production,relatively more oxidative substances such as O3, H2O2 and HClOwill be created when electrolysis is on the way. Coupled with the frequent anodizing reversion, electrode made from common materials can be easily run out. As we understand superior properties of titanium are more than light, strong, corrosion-resistant but also highly resistant to chlorine in the atmosphere which make it much more durable. Coating with 99.99%Platinum Group Metals (PGM), i.e. platinum, rhodium or iridium, titanium anodes are highly electric conducive, catalytic and oxidation-resistant, as well as energy efficient. Compared with longer period of use life which is multiple folds of other materials, titanium anodes with PGM coating are also economical application to assembly facilities at water treatment plants. Also, titanium anodes are also recommended to be applied in trivalent chromium, ceramic composite, gold and silver electroplating, as they are greatly corrosion and chloride resistant. |